Problem Solving

Problem solving can take many forms but, if you try to solve your problem without any structure, you may end up with a bigger issue than you started with !.

Definition of Problem :

Something that needs a solution.

Can be either positive or negative.

Frequencies:

• Chronic - Ongoing and Accepted problems

• Spasmodic - Sudden change to normal process.

Problem Levels

Level 0 - Abnormality only affecting those directly related to the process and contained.

Level 1 - Abnormality that affects the processes ability to achieve Q,C and D.

Level 2 - Abnormality that affects the next process and may have an impact on the final customer.

Level 3 - Abnormality that has affected the final customer.

Analysis of Problems

Qualitative tools

• Tools which are used to obtain and structure ideas during the cycle

Flow chart

5 why

Brainstorming

Cause & effect diagram (Ishikawa, fishbone)

Quantitative Tools

• Tools that are used to gather and analysis numerical data during the cycle.

Checksheets

Pareto

Control charts

Histograms

Scatter diagrams

The 5 Principles :-

• Problem Definition

• Identify Root Cause

• Customer Protection and Countermeasure(s)

• Confirm Effectiveness of Countermeasure

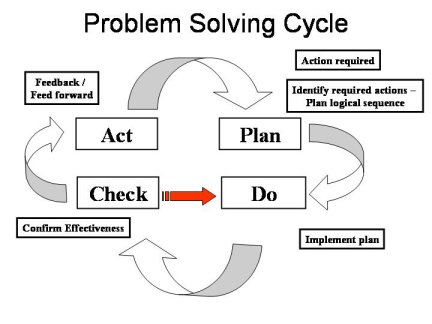

• Feedback / Feed forward

The different types of problem solving

Preventative:

• This looks at putting in place solutions prior to abnormalities occurring. Best identified during the design stage prior to transfer to manufacturing using Advanced Quality Tools.

Pro- active:

• This looks at the current standards and by analysing data using the 7 quality control tools seeks to make kaizen improvements.

Reactive:

• This looks at the abnormalities that have occurred and by gathering and analysing data using some of the 7 quality control tools aims to provide a customer protection and countermeasure .