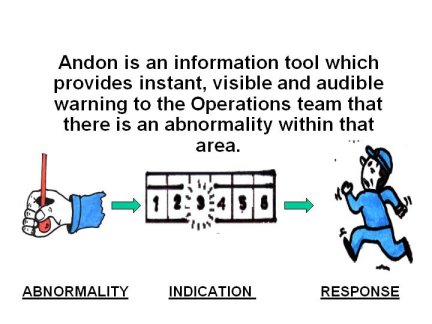

Andon

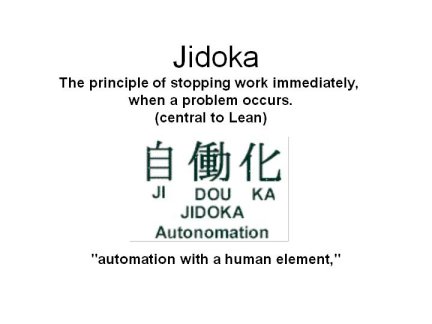

Andon is one of the three elements that make up the principle of Jidoka -

Jidoka and Andon

Jidoka is made up of three elements, these are: -

1. Andon

2.Full work system

3.Error proofing (pokayoke)

So exactly what does andon look like?

A full training module for Andon is contained within our Lean Six Sigma Certification course materials.

What an Andon-System does:-

l. Allows timely corrective actions by alerting personnel when abnormal conditions occur.

2. Allows Shop floor Team Leaders to spend less time and effort monitoring the situation, and more time solving abnormalities.

3. Allows Operation teams to monitor equipment and personnel more effectively.

4. It can act as a 2 way communication device e.g. When indicator returns to green; this tells everybody it’s ‘back to normal’

What the System doesn’t do:-

l. Solve Abnormalities

2. Prevent all defects from being passed forward

3. Replace good verbal communication between work groups

4. Remove the need for rectification or customer protection

Direct Benefits:

Control the production

Operators have the ability to ‘stop call wait’

Defect reportability & correction, operators can report faults immediately and countermeasures can be implemented at source

Safety/ ergonomics, identifies safety and body stress concerns. Even loading (balanced processes) will allow rebalance of process if over burden occurs

Workable design highlights problems with work density

Implementation Guidelines:

• Implement following Standard Operations – stability

• Team structure / ratio / roles and responsibility

• Identify work zones / stations

• Divide the process into manageable steps

• Determine what conditions must be measured

• Design the board

• Set the escalation procedure

• Determine the support structure

• Set the criteria for collating downtime data

• Determine confirmation points / regularity

•Set effective communication structure

•Visualise problem solving status

•Andon systems should be thought out and appropriate in design to be effective.

•The systems should be implemented when and only when an appropriate support system and escalation procedure is in place (Service Level Agreements, problem solving process etc.)

•Signals should be simple and easy to understand

•Avoid spending too much money on a ‘State of the art’ System, prove the system out with a simple manual system to judge it’s worth