What Is Lean Manufacturing ?

Here Is a Basic Lean Manufacturing Definition ...

People often ask the question " What is Lean Manufacturing ?" Lean should be recognised as a totally different way of looking at manufacturing. It’s about attacking waste; the massive areas in the value stream (manufacturing process), from raw material to finished goods, where no added value is taking place.

‘Lean thinking’ first appeared in the 1920s Henry Ford used it to improve his manufacturing flow lines while producing his famous Ford model T.

He used it to rid his company’s production lines of all waste, be it an activity or other form of waste, so he could meet his vast order schedule. Lean carried on in its infant form up to the seventies, where the global oil crisis demanded that petrol-guzzling engines, (that Ford had become used to making), be replaced by economical smaller engines.

This is when lean was adopted by Japan and the Toyota car company. Here it was refined to the present standard we are accustomed to.

So what is lean manufacturing ? As already stated it’s the removal of waste from our business, but what do we class as waste.

There are seven wastes and they are as follows;

OVERPRODUCTION

e.g. making it for the sake of it

INVENTORY

e.g. high raw material stocks

WAITING

e.g. long set ups and times

MOTION

e.g. walking lifting putting down

TRANSPORTATION

e.g. unnecessary movement / extra handling

REWORK

e.g. customer satisfaction / right first time

OVERPROCESSING

e.g. fresh air cutting / speeds and feeds

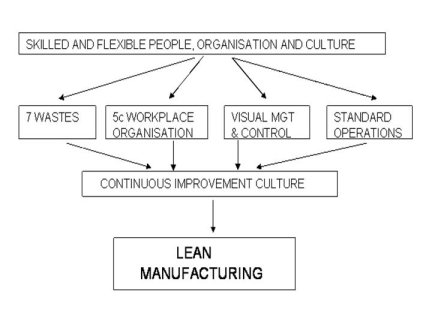

But just removing waste only is not enough, so that’s where the other lean principles come into practice.

They cover all aspects of production in any environment and can be used by anyone who wants to improve his or her working environment and production processes.

Lean Consists of the following Elements...

What is Lean Manufacturing ?

LEAN THINKING AIMS

QUALITY

Built in quality

Zero defects / PPM

Route cause analysis

Everybody involved

COST

Increased capacity

Capital spend reduction

Optimised inventory level

Productivity increase.

DELIVERY

Drumbeat manufacture

Reliable and consistent

Responsive to fluctuation Lowest possible lead-time

TRADITIONAL FOCUS:

WORK HARDER FASTER FOR LONGER

LEAN APPROACH:

IMPROVE THE PROCESS TO ELIMINATE WASTE AND TO WORK SMARTER / SAFER

And always remember, without standardisation there can be NO improvement.

This is the basic building block of all improvement activities, so if you are asked what is lean manufacturing, always start with this.