- Home

- What is 5S ?

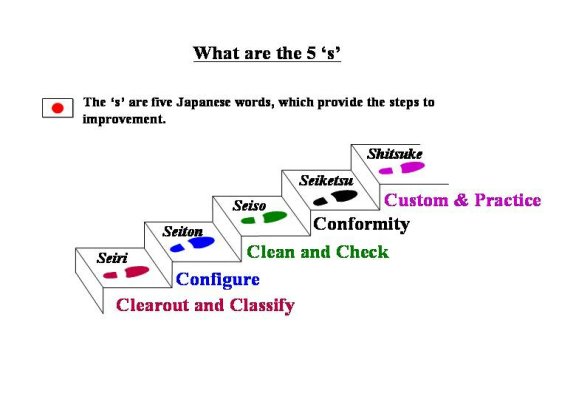

5S - Workplace Organisation... And Much More!

5S Can Form The Basis Of Your Production System

5S is in place in ALL world class organizations.

It aims to :-

· Remove waste from the workplace.

· Provide reduction in non value added activities.

· Provide an environment where continuous improvement is embraced.

· Improve safety.

· Increase quality.

5S Step 1 (Seiri) Sort

Clear-out and Classify

Identify

what you KNOW you definitely need all the time.

what you KNOW you definitely need occasionally.

what you THINK you might need in the future.

what you THINK you no longer need.

Never Assume. Ensure that everyone is in agreement.

Check to make sure that what you think becomes what you KNOW.

Remember! Redundant items cost money to store - If you don't need it don't keep it!

Step 1 (Seiri)

Eliminating Waste - Action at the source

7 steps to follow :-

1. Determine the extent of the dirt / leakages.

2. Undertake major cleaning.

3. Investigate the reasons why.

4. Determine the worst locations within site / area.

5. List up the reasons in detail.

6. Decide on an effective Action Policy.

7. Budget and schedule implementation plan (if necessary).

Step 2 (Seiton) Set in Order

Configure

Put Everything in its correct place

Organise storage for all equipment i.e. what, where, how many.

Frequency of use defines location relative to point of use.

If its used frequently keep it close / low frequency store offline.

Shop organisation must have clear walkways, work areas, rest areas. etc.

Consider using different coloured floor areas to highlight walkways, work, storage areas etc.

All essentials such as fire extinguishers and safety equipment must be visible

and easily accessible.

The place must be

Appropriate to usage

Well maintained

Tools Easily located

Tools / locations Clearly identified

- A place for everything and everything in its place

5S Step 3 (Seiso) Shine

Clean and Check

Regular cleaning schedules are required

Create a clean and tidy working environment and maintain it.

Define responsibility zones for cleaning areas, and clarify roles and responsibilities.

Develop regular routines for maintaining a clean environment (e.g.. 5 min 5 S etc).

Cleaning must become an activity which is:

Ongoing

Monitored

A source of pride

Seen as a value added contribution

Cleanliness is the basis of quality. Once the workplace is clean it must be maintained.

Creating a spotless workplace:

Step 4 (Seiketsu) Standardize

Conformity

Good Housekeeping

Decide what is classed as an abnormality and make it visible to the operator.

Design clear, standard labels for locations, tools, machine conditions and locate them in standard positions.

Provide indicators where limits can be exceeded.

Draw position markers in places where items are removed and returned.

Agree and set :

Standards of cleanliness.

Procedures for maintaining standards.

Standard marking and labelling of all items.

Standard methods for indicating limits, identifying locations, etc.

The system must be controlled and maintained.

5S Step 5 (Shitsuke) Sustain

Custom and Practice

Adhere to the system rules

Develop and maintain habits through training and discipline. (At all times)

Use visual rather than verbal communication to train for new procedures.

Involve everyone in the development of standard documentation.(e.g.. Check sheets etc.)

Be conscious of time (3-10min).

It is important to maintain discipline

Incorrect practices must be identified.

Correct practices have to be taught and demonstrated.

Ensure everyone's understanding and agreement.

Without training and discipline the other steps will fail

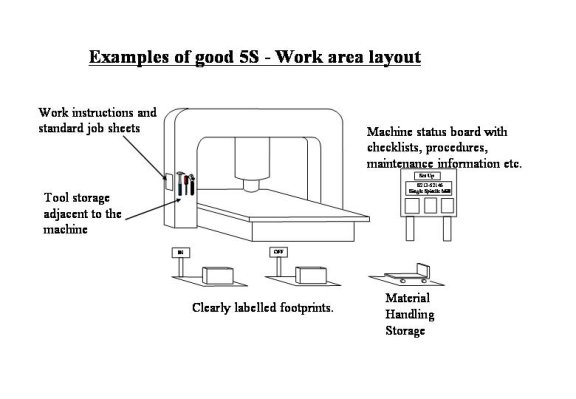

Examples of good 5S

5S Training & Lean Six Sigma Certification...

The building block for continuous improvement