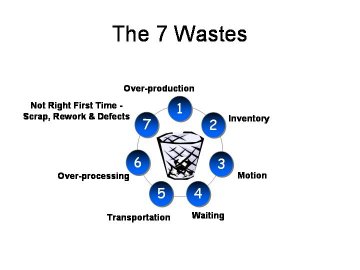

The 7 Wastes (Seven forms of Muda)

7 wastes module included in all courses - For a very limited time get a massive 90% discount on our Lean Six Sigma Training and Certification courses and future-proof your skillset.

The 7 Wastes explained

Waste is the use of any material or resource beyond what the customer requires and is willing to pay for.

Lean Manufacturing aims to identify and eliminate waste to improve the performance of the business.

Shigeo Shingo identified “Seven” forms of waste (Plus one – The eighth waste, underutilization of people). These 7 forms of waste are shown below

1. Overproduction

• To produce sooner, faster or in greater quantities than the absolute customer demand

• Manufacturing too much, too early or “Just in Case”

• Overproduction discourages a smooth flow of goods or services

• Takes the focus away from what the customer really wants

• Leads to excessive inventory

Caused by:

• MRP push rather than kanban pull

• Large batch sizes

• Looks better to be busy!

• Poor people utilisation

• Lack of customer focus

Why one of the 7 wastes ?:

• Costs money

• Consumes resource ahead of plan

• Creates inventory

• Hides inventory/defect problems

• Space utilisation

2. Inventory

Any raw material, work in progress (WIP) or finished goods which are not having value added to them

Caused by:

• Production schedule not level

• Inaccurate forecasting

• Excessive downtime/set up

• Push instead of pull

• Large batching

• Unreliable suppliers

Why one of the 7 Wastes ?:

• Adds cost

• Extra storage space required

• Extra resource to manage

• Hides shortages & defects

• Can become damaged

• Shelf life expires

3. Motion

• Adds cost

• Motion is the movement of “man”

• Waste motion occurs when individuals move more than is necessary for the process to be completed

Caused by:

• No standard operating procedure

• Poor housekeeping

• Badly designed cell

• Inadequate training

Why one of the 7 Wastes ?:

• It interrupts production flow

• Increases production time

• Can cause injury

People or parts that wait for a work cycle to be completed

• Where are the bottlenecks?

• What are the major causes of lost machine availability?

• What are we doing to improve machine availability?

• Do people wait on machinery?

Caused by:

• Shortages & unreliable supply chain

• Lack of multi-skilling/flexibility

• Downtime/Breakdown

• Ineffective production planning

• Quality,design,engineering Issues

• ‘Black art’ processes

Why one of the 7 Wastes ?:

• Stop/start production

• Poor workflow continuity

• Causes bottlenecks

• Long lead times

• Failed delivery dates

5. Transportation

Unnecessary movement of parts between processes

• Complex material flow paths

• Poor close coupling

• Wasted floor space

• Unnecessary material handling

• Potential damage to products

Caused by:

• Badly designed process/cell

• Poor value stream flow

• Complex material flows

• Sharing of equipment

Why one of the Seven Wastes ?:

• Increases production time

• It consumes resource & floorspace

• Poor communication

• Increases work in progress

• Potential damage to products

6. Over-Processing

Processing beyond the standard required by the customer

By improving processing efficiency we ultimately use less resource to achieve the same customer satisfaction

Caused by:

• Out of date standards

• Attitude - ‘Always done it like this’

• Not understanding the process

• Lack of innovation & improvement

• Lack of standard operation procedures

Why one of the Seven Wastes ?:

• It consumes resource

• It increases production time

• It’s work above and beyond specification

• Can reduce life of component

7. Non-Right First Time (Scrap, Rework and Defects)

A defect is a component which the customer would deem unacceptable to pass the quality standard

• Defects reduce or discourage customer satisfaction

• Defects have to be rectified

• Rectification costs money with regard to time effort and materials

• Defects in the field will lose customers

• Right first time is the key

Caused by:

• Out of control/Incapable processes

• Lack of skill,training & on the job support

• Inaccurate design & engineering

• Machine inaccuracy

• Black art processes

Why one of the 7 Wastes ?:

• Adds costs

• It interrupts the scheduled

• It consumes resources

• It creates paper work

• Reduces customer confidence

See products relating to the -

The 8th Waste

Under utilisation of people. People are your greatest asset, learn to get the best out of them.