Value stream mapping

Value Stream Mapping - What is it?

Toyota have been benefiting from Material & Information Flow Mapping ( Value stream mapping ) since 1940’s

Taiichi Ohno could not see waste at a glance (especially across a geographical area)

He developed Material & Information Flow Mapping (VSM) as a standard method for mapping the flows visually

Became the standard basis for designing improvements at Toyota - as a common language. It became one of their business planning tools

VSM is now utilised throughout the world, in many businesses to strategically plan

VSM is the start to any lean transformation -

“Where you can flow you flow

Where you can’t flow - You Pull !

A Value Stream Map is a diagram of all actions (both value added and non-value added) required to bring a product through from raw material to the arms of the customers

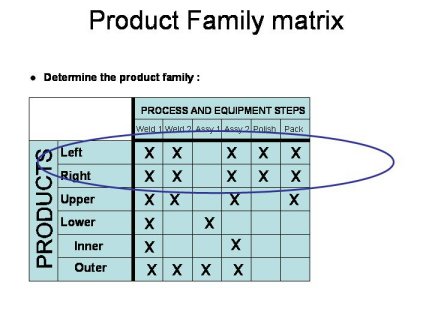

Before you begin Mapping you need to identify a product family – Use a product family matrix to accomplish this –

7 steps to current state value stream mapping

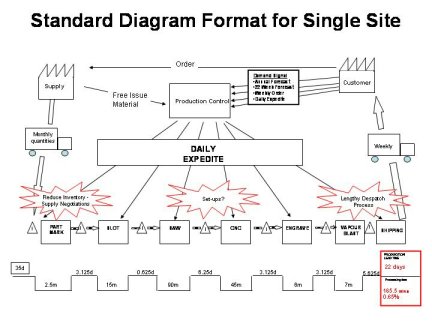

• Diagram needs to be on one sheet of paper

• Use the standard format for the diagram

• Use the standard symbols for the diagram

• Capture all of the data yourself

• Walk, Understand and Validate the process

• Involve as many people as practical

• Use paper and pencil

You should end up with a value stream map looking similar to this...

Summary

Collect data across a value stream.

Use the 7 steps to draw a current state Value Stream Map.

Use the 9 questions and 7 steps to draw a future state Map.

Identify your Material/Information loops.

Decide the order to tackle the loops.

Write the Tactical Implementation Plan

• Set objectives for each loop as required to achieve the future state

• Set measurable goals for each objective

• Use the 9 questions within each loop to set an order of work

• Set milestones and write up the plan

• Get formal agreement from all concerned

The leader of each work stream should produce their own execution schedule showing how to achieve each goal by it’s milestone.

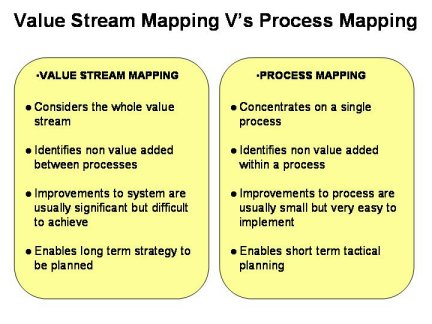

One final question many people ask – What is the difference between a Value stream map and a Process Map ?

Stop playing at improvements! Get LSS Black Belt Certified

Includes Current State and Future State training material for - Value Stream Mapping