TPM - Total Productive Maintenance

Lean Six Sigma Training including TPM modules

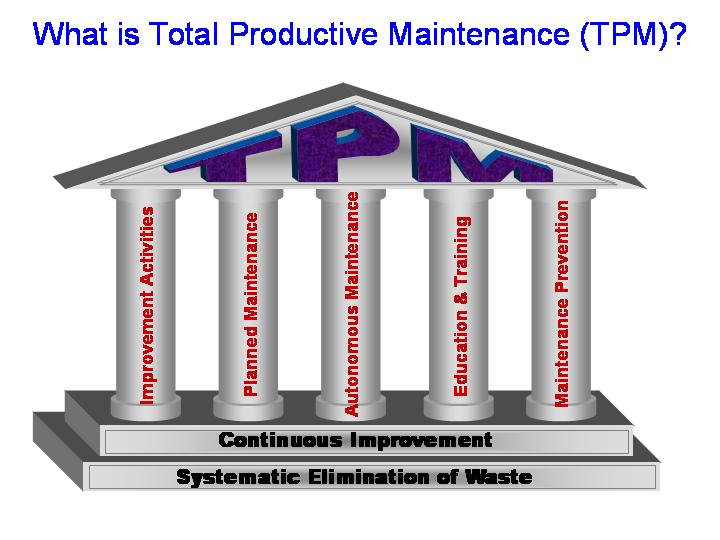

What is Total Productive Maintenance ( TPM ) ?

A system of maintenance covering the entire life of the equipment and the total human resource.

•It is a tried and tested way of eliminating waste, saving money and making factories better places to work.

•It gives operators the knowledge and confidence to manage their own machines.

•It is a long term process to increase skills, raise efficiency and achieve zero losses.

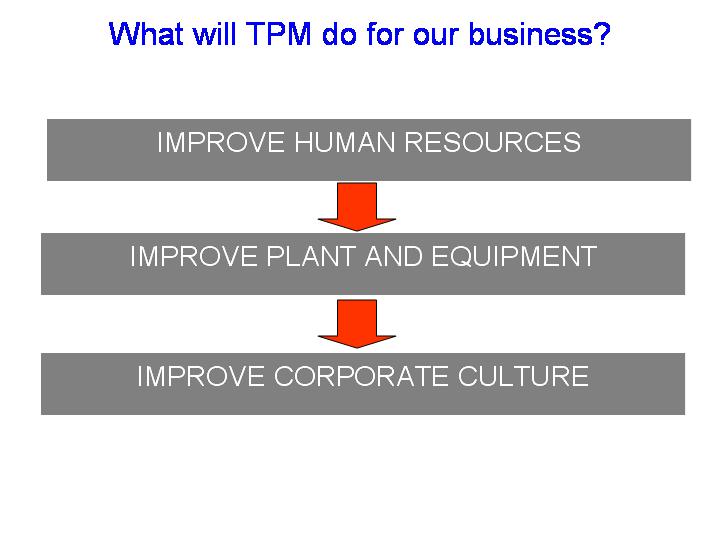

What are the benefits of TPM ?

Total Productive Maintenance refuses to accept that machine inevitably fail.

•It reduces the total life-cycle costs of equipment.

•It simply reminds us that every time a machine fails, something could have been done to prevent it.

•Gradually the operator’s become maintainers.

•Gradually the maintainers become improvers.

•It develops the five senses, as well as technical skills.

What is Effective Maintenance ?

PLANNED MAINTENANCE

“ The scheduling of maintenance activities on a time based or usage basis regardless of the current performance levels of the equipment”

•PREVENTATIVE MAINTENANCE

“ A systematic approach to eliminate catastrophic failure/breakdowns through regular care and attention, early diagnosis and rectification”

•PREDICTIVE MAINTENANCE

“ A systematic approach utilising history and equipment condition monitoring to predict and prevent catastrophic failure/breakdowns ”

•BREAKDOWN MAINTENANCE

“ When all else fails ensuring that equipment availability is achieved in the shortest possible time whilst eliminating root cause faults with sustainable repairs”

•EFFECTIVE EQUIPMENT DESIGN

“ A systematic approach to equipment design which maximises equipment availability, minimises life cycle costs and eliminates waste”

What is Autonomous Maintenance ?

An operator skills development programme.

•Allows problems to be identified and solved quickly.

•Stops accelerated deterioration of plant and equipment.

•An approach to stop deterioration related failures.

•Stabilises equipment conditions (standards).

•Develop training materials on how to run, operate & maintain equipment.

What is Overall Equipment Effectiveness ( OEE )?

Overall Equipment Effectiveness (OEE) is a total measure of performance that relates the availability of the process to the productivity and quality.

•OEE is the Key Performance Indicator (KPI) for Total Productive Maintenance.

•OEE will measure the impact of change on a process caused by eliminating process, or equipment losses.

•A World Class Company should achieve 85% OEE on key equipment

What is Quick Changeover or SMED ?

Quick Changeover is a method of analysing and reducing the time needed to change a process from producing one good part to producing the next good part part.

•It is a driver for standardisation.

•It is one of the 6 Big Losses.

•Quick changeovers are an enabler for flow.

•Often referred to as “Single Minute Exchange of Die” (SMED).