Overview of Six Sigma

This overview of Six Sigma is a brief explanation of the basic concepts, meant as a quick reference guide.

What is Six Sigma?

Six Sigma is an effective business process improvement methodology.

It is not the Business of Quality.

It is the Quality of Business

It focuses on customers needs.

Customers can be:

external

internal

Six Sigma was developed at Motorola. It has since helped a number of world-class organizations, including General Electric, become more cost-competitive while achieving strong growth.

Why do Six Sigma?

Make us meet our customers increasing expectations

Boost our growth in line with that of our core customers

Enhance the value of the Company

Provide a consistent methodology of improvement

Six Sigma definitions

Sigma measures how far a process or product deviates from a target goal.

One Sigma = high variance from the goal (many defects)

Six Sigma = low variance from the goal (few defects)

In other words:

Six Sigma = 3.4 defects per million opportunities

Four Sigma = 6,210 defects per million opportunities

Three Sigma = 66,807 defects per million opportunities

Six Sigma is -

a statistical bench mark

sigma stands for variance of a measurable characteristic

The overview of Six Sigma improvement methodology is DMAIC

Define

Identify the product or process to be improved and top few critical to quality (CTQ) customer requirements.

Measure

Quantify how the process performs today and set improvement goal

Analyze

Identify the input variables that affect the CTQ's the most

Improve

Determine solutions for controlling the key process input variables, quantify their impact and compare to goal.

Control

Implement process design modifications and standardization methods for maintaining the improved performance level over time.

Six Sigma is Data Driven..

Initial process performance is quantified to establish baseline.

Data collection is planned to ensure it is information rich and statistically significant.

Data is appropriately graphed to unveil information.

Inferences are made using sound sampling techniques.

Causes are verified with data.

Solutions are validated with data.

The Foundation of Six Sigma is Data-Based Decision Making

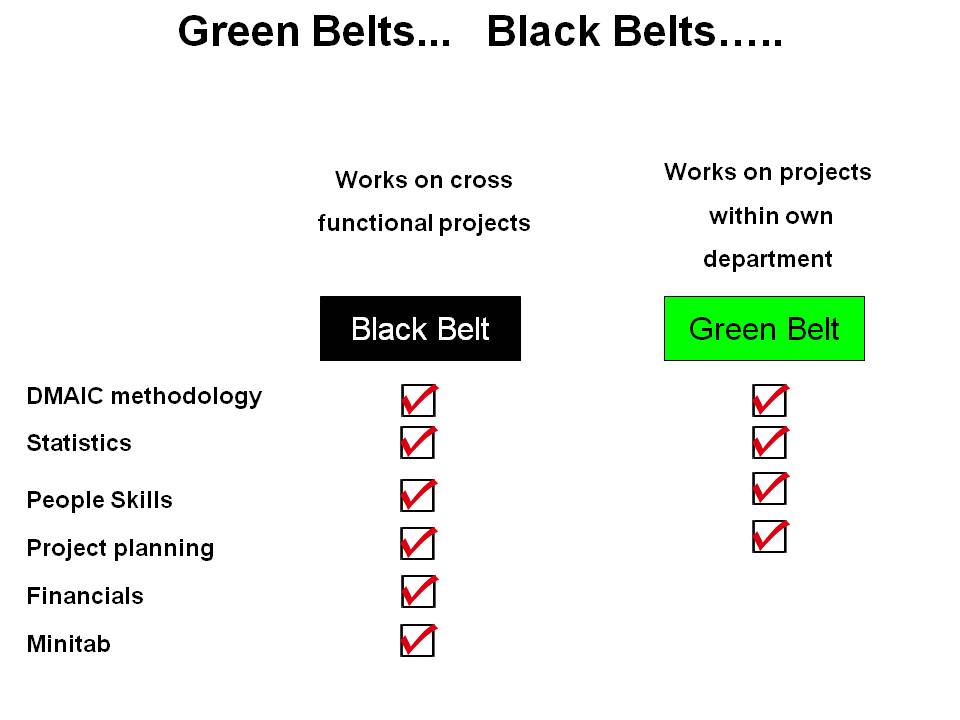

The key to six sigma implementation is the training and certification of green and black belts. For details of the easiest online method click this link -