Your Headquarters for Lean Six Sigma & Operational Excellence Deployment, Coaching and Skills Transfer

Sign up for our weekly newsletter for updates, articles and free giveaways of case studies, templates and training materials every issue! Simply enter your e-mail on the right

Let me introduce you to my journey - I am passionate about Lean Six Sigma, and want to share my knowledge.

I’d like to give you a brief introduction to myself and an insight into what makes me tick.

I started in the improvement business quite by accident back in 1994 when, while working as a service manager of a prestige and performance vehicle dealership, I was tasked with making the dealership more profitable and was sent on a training course to learn how to do this.

Some of the things I learned were the

basics of capacity and demand planning, visual management, workplace organisation,

standardised work and performance management systems, which I promptly began to

implement in the business under my control – with astounding success.

Profits went up, costs went down and it continued for another 4 years as I worked my way through to the Production Director position (Grand title – poor pay!). Prior to this I’d started my working life in engineering, completed my apprenticeship and Higher National qualification before deciding to leave this and move into sales, where the real money was (or so I thought! this however was to be a vital part of my education for my later career in consultancy training and coaching).

Anyway, back to the point, in 1999 I

decided that the weekend working and long hours in the automotive dealership

wasn’t for me and made the move back into engineering, Aerospace engineering to

be exact, just at the time when the Lean revolution was hitting the Aerospace

industry and all the things I’d been implementing for the past 5 years were in

that very large ‘Lean’ toolbox (albeit under a Japanese name). I spent 6

years in the Aerospace industry, working as an internal consultant alongside

some of the most knowledgeable Lean practitioners you could ever wish to meet,

many of them ex-Toyota managers and all trained over in Japan (one of whom used

to share a desk with Toyoda San himself!).

In 2005 I moved out of my comfort zone and into Airline catering (Fast Moving Consumer Goods), where the takt time went from days in the Aerospace industry to seconds in the catering industry. It was here that the requirement for my six sigma education became apparent in order to deliver what the customer needed from me (I always believe the methodology is less important than applying the correct solution for the problem at hand – Lean or Six Sigma should never be a question that is asked, just ‘How do we solve the problem at hand?’).

So, after setting up Beyondlean In 2006 and delivering tens of millions in benefits (I really wish some of those contracts had been profit shares!) to clients across the UK, from big 4 banks to major Media corporations and through into major government depts., here I am hoping to pass on some of that knowledge and experience to you.

What can Lean Six Sigma do for you and your business?

Every business is set up perfectly - to deliver exactly the results it currently gets. The successful ones go from strength to strength while others seemingly lurch from crisis to crisis. Yet how is it that two equally capable competitors see one of them grow and one of them fail?

The difference, for a majority of the truly successful ones, is a proficiency in, and a strict adherence to the core principles of Lean Six Sigma. No "magic tricks" or "getting lucky" involved.

Is your business, department or division currently struggling in the areas of efficiency, quality, on time delivery to customers and rising costs? Then you are not alone but simply in the same boat as 99% of all other businesses.

That's the bad news.

The good news is that we're here to help you improve, so that you and your enterprise can become more successful in becoming more efficient, more cost-effective, while consistently delivering high quality products and services to a loyal and growing customer base.

|

|

And even more good news. It doesn't have to be painful, disruptive, or expensive.

So where do you start if you're serious about fixing things?

Easy. By taking advantage of our complimentary business assessment tool, along with the special, unadvertised bonus 'Standard Business Roadmap' e-mail course.

This highly effective, yet easy to understand and implement, combination of tools and training will give you a great starting point in identifying where some of your opportunities may lie and will help to provide a comprehensive roadmap to deliver them.

Even if it only helps you spot one new growth opportunity, it will have been worth 100 times the cost of your time to read it!

Over the Past 15 years, we have worked with a wide array of companies in several different sectors, saving them in excess of £20 million in documented benefits, as well as improvements to delivery lead times, reduction in risk exposure and quality improvements.

Let us help you effect the kinds of growth, savings and efficiencies that up until now seemed unreachable at any cost.

Lean Six Sigma Green Belt & Black Belt Certification

Why Lean Six Sigma Training & Certification?

We are currently running a limited-time-only marketing test and are giving you a massive 90% discount on all our Lean Six Sigma Certification courses. Act now and take advantage!

The risk of global recession is set to be with us for the next few years and one sector, more than any other is set to be in great demand – Business Improvement Professionals.

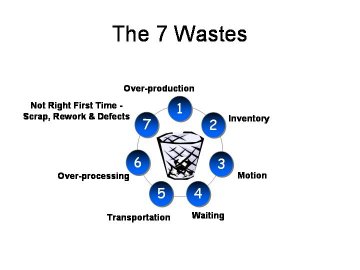

Businesses must remove excess costs from their operations to remain viable. They need to increase profitability and productivity, remove waste and variation from their processes in order to stay in business and remain competitive.

How will they do this? By employing Lean and Six Sigma (Lean Six Sigma Training & Lean Certification Online) methodologies as part of their business as usual.

These skills are in great demand and there are a lot of experienced Lean Six Sigma professionals out there. The only way to ensure you get to the front of the queue and to the top of the earnings ladder is to become a Certified Lean Six Sigma Black Belt.

Our online Green Belt and Black Belt students deliver an average of £50,000+ in tangible benefits as a result of completing the course and in many instances have been promoted as a result.

Let us help you get Lean Six Sigma certified and to experience the career growth and pay raise that comes with it.

Lean Six Sigma Business Diagnostic

Are you are a small company with a limited budget looking for information or advice, or maybe wanting to get hold of some basic training material to roll out yourself in areas you have identified as needing some attention ? Whatever your needs, we will be able to help. Even if it's just some advice you need!

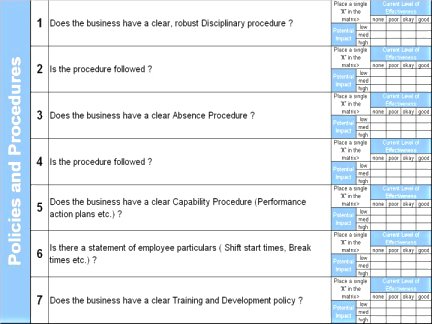

Have a look at our latest service offering - The 'Business Operations Diagnostic'. This is perfect if you have a limited budget. This service really does put the 'Big 4' Consultancy advice within reach of ALL businesses. Including yours!

Our mission is a simple one. We aim to provide YOU with the tools and knowledge to change YOUR business........In short we'll help you to help yourself.

We have developed a system that will work for any business. Yours especially.

A full breakdown of this is contained in our Lean Six Sigma Black Belt Training & Certification course, details of which are available at Online Black Belt Training & Certification